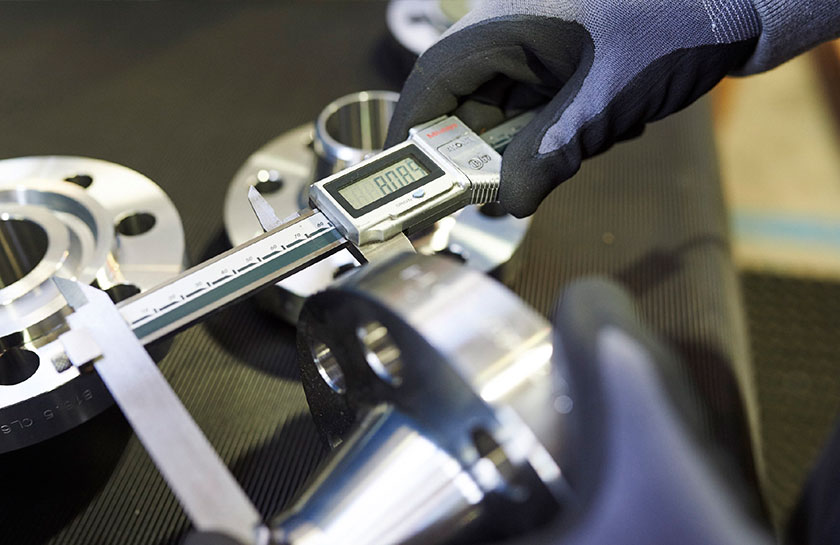

Material testing under extreme conditions

Pipes and pipe connection parts are often subjected to extreme stresses in real life. We test these parts according to your specifications to ensure they will withstand these mechanical, thermal and chemical stresses, to your specifications.

We work with competent accredited testing laboratories – although this should go without saying. We would also be pleased to arrange independent approval for all major bidders. Please do not hesitate to call us with any questions you may have about testing and approval.

Our material testing services

Material testing at rff includes various test methods to determine material behaviour and parameters in standardised material samples or finished components subjected to a wide variety of stresses.

We will check the material for purity, defects and endurance. Our component testing services always involve accredited testing laboratories that use the following destructive and non-destructive testing methods:

- Destructive testing methods

Tensile and impact testing - Non-destructive testing methods

Radiographic and ultrasonic testing, eddy current testing, magnetic particle and dye penetrant testing, hardness testing, roughness measurement, spectral analysis

Independent approval testing

We will also arrange for your components to be tested by independent approval testing companies according to DIN EN 10204/3.2. We work with all major notified bodies including:

- Technischer Überwachungsverein (TÜV)

- DEKRA

- De Norske Vertias (DNV)

- Lloyds Register (LR)

- Bureau Veritas (BV)

- American Bureau of Shipping (ABS)

- Registro Italiano Navale (RINA)

- Korean Register (KR)

.jpg)